How to Scale Soap Recipes: Complete Guide to Batch Size Conversion

Learn how to scale soap recipes up or down accurately. Includes formulas, examples, and tips for maintaining perfect ratios when changing batch sizes.

Quick Answer

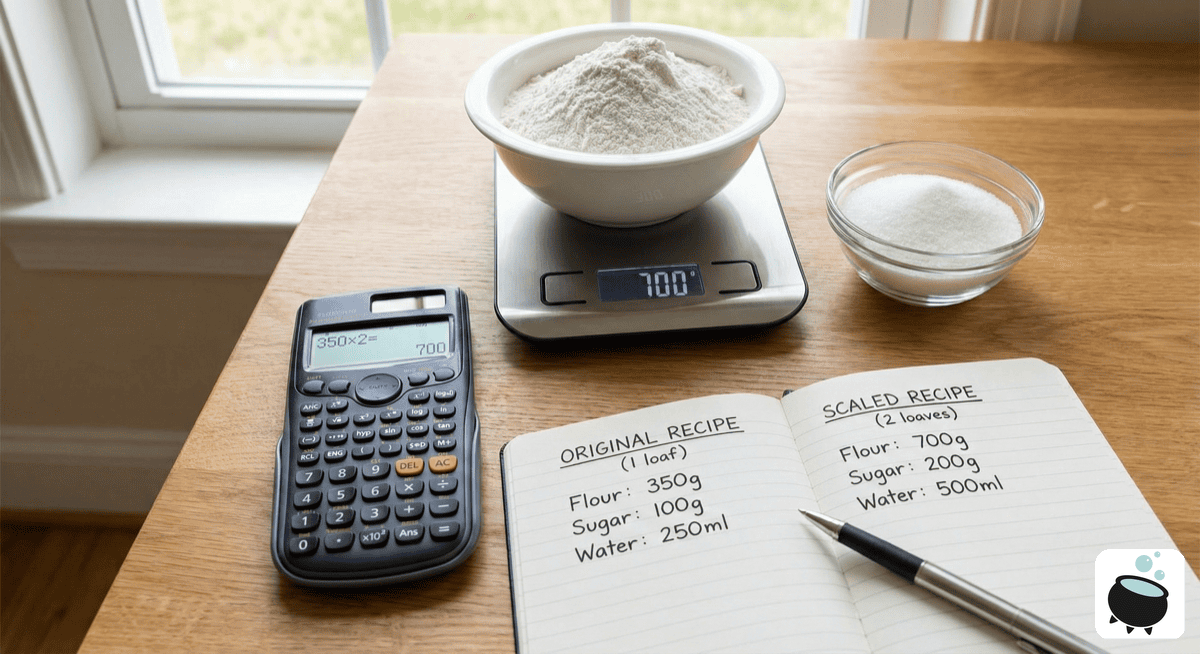

To scale a soap recipe, multiply every ingredient by the same scaling factor. Scaling factor = desired batch size ÷ original batch size. If a recipe makes 2 lbs and you want 5 lbs, multiply all ingredients by 2.5 (5÷2). Never round lye measurements—use precise calculations.

Why Scale Soap Recipes?

Soap makers need to scale recipes for many reasons:

- Testing new formulas - Make small batches to minimize waste

- Production increase - Scale up successful recipes for selling

- Mold fitting - Adjust recipes to fit specific mold sizes

- Ingredient constraints - Work with the amount of oil you have

- Cost efficiency - Larger batches often mean better per-bar costs

The Basic Scaling Formula

Scaling Factor = Desired Size ÷ Original Size

New Amount = Original Amount × Scaling Factor

This formula applies to:

- All oils and butters

- Lye (sodium hydroxide or potassium hydroxide)

- Water or other liquids

- Fragrances and essential oils

- Colorants and additives

Step-by-Step Scaling Example

Original Recipe (1 lb batch):

- Olive oil: 8 oz

- Coconut oil: 5 oz

- Shea butter: 3 oz

- Sodium hydroxide: 2.23 oz

- Distilled water: 5.58 oz

Scaling to 3 lbs:

Step 1: Calculate scaling factor

- 3 lbs ÷ 1 lb = 3.0

Step 2: Multiply each ingredient

- Olive oil: 8 oz × 3 = 24 oz

- Coconut oil: 5 oz × 3 = 15 oz

- Shea butter: 3 oz × 3 = 9 oz

- Sodium hydroxide: 2.23 oz × 3 = 6.69 oz

- Distilled water: 5.58 oz × 3 = 16.74 oz

Scaling to 8 oz (half batch):

Step 1: Calculate scaling factor

- 8 oz ÷ 16 oz = 0.5

Step 2: Multiply each ingredient

- Olive oil: 8 oz × 0.5 = 4 oz

- Coconut oil: 5 oz × 0.5 = 2.5 oz

- Shea butter: 3 oz × 0.5 = 1.5 oz

- Sodium hydroxide: 2.23 oz × 0.5 = 1.115 oz

- Distilled water: 5.58 oz × 0.5 = 2.79 oz

Scaling by Mold Size

If you're scaling to fit a specific mold:

Step 1: Calculate Mold Volume

- Length × Width × Height = Volume in cubic inches

- Example: 10" × 3.5" × 3" = 105 cubic inches

Step 2: Convert to Oil Weight

- General rule: 0.4 oz of oils per cubic inch

- 105 cubic inches × 0.4 = 42 oz of oils needed

Step 3: Calculate Scaling Factor

- If original recipe uses 16 oz oils

- 42 oz ÷ 16 oz = 2.625 scaling factor

Step 4: Apply to All Ingredients

- Multiply everything by 2.625

Critical Scaling Rules

DO: Keep Ratios Exact

Every ingredient must be multiplied by exactly the same factor. Even small variations compound into significant differences.

DON'T: Round Lye Amounts

Never round lye to convenient numbers. 2.23 oz scaled by 3 is 6.69 oz, not "about 6.5" or "close to 7."

DO: Double-Check Math

Use a calculator. Better yet, use soap making software that scales automatically.

DON'T: Eyeball Measurements

Always use a digital scale accurate to 0.01 oz or 1 gram.

Scaling Fragrance and Additives

Fragrances and Essential Oils

These scale directly with your oils:

- Standard fragrance rate: 0.7 oz per pound of oils

- If scaling oils by 2.5×, multiply fragrance by 2.5× too

Colorants

Most colorants scale linearly, but:

- Start with slightly less in larger batches

- Add more if needed after mixing

- Some colorants (micas, oxides) are very concentrated

Exfoliants and Botanicals

These generally scale directly:

- Oatmeal: usually 1 tablespoon per pound of oils

- Scale proportionally with batch size

Common Scaling Mistakes

| Mistake | Consequence | Solution |

|---|---|---|

| Rounding lye | Lye-heavy or lye-light soap | Use exact calculations |

| Forgetting an ingredient | Unbalanced recipe | Use a checklist |

| Mixing units | Wildly wrong amounts | Convert everything first |

| Mental math errors | Ruined batches | Always use calculator |

| Scaling percentages wrong | Incorrect ratios | Verify math twice |

Using Percentages for Easy Scaling

Many experienced soap makers create recipes in percentages for easier scaling:

Percentage-Based Recipe:

- Olive oil: 50%

- Coconut oil: 31.25%

- Shea butter: 18.75%

To Scale:

- Decide total oil weight (e.g., 32 oz)

- Multiply: 32 oz × 0.50 = 16 oz olive oil

- Multiply: 32 oz × 0.3125 = 10 oz coconut oil

- Multiply: 32 oz × 0.1875 = 6 oz shea butter

- Run new oil weights through lye calculator

Scaling Up: Production Considerations

When scaling recipes significantly larger, consider:

Equipment Limitations

- Is your pot large enough?

- Can your immersion blender handle the volume?

- Do you have adequate mold capacity?

Timing Changes

- Larger batches may trace faster or slower

- Allow more time for mixing

- Temperature management becomes more critical

Workspace Safety

- More lye means more safety precautions

- Better ventilation needed

- Larger spill potential

Scaling Down: Testing Considerations

When making small test batches:

Minimum Practical Size

- Below 8 oz of oils becomes impractical

- Small measurement errors have bigger impact

- May not fill standard test molds

Scale Accuracy

- Need a precise scale (0.01 oz or 1 gram)

- Small errors compound in tiny batches

- Consider slightly larger test batches (16 oz)

Frequently Asked Questions

Can I scale a recipe by any amount?

Yes, any scaling factor works mathematically. However, very small batches (under 8 oz oils) become impractical, and very large batches may exceed your equipment capacity.

Do I need to recalculate lye when scaling?

If you're scaling all oils by the same factor, you can scale the lye by the same factor. However, it's safer to recalculate lye using a calculator to verify accuracy, especially for large batches.

Why does my scaled recipe behave differently?

Larger batches hold heat longer (may accelerate faster), while smaller batches cool quickly. Temperature management becomes more important as you change batch sizes.

Can I scale hot process and cold process recipes the same way?

Yes, the scaling math is identical. However, hot process requires appropriately sized cooking vessels.

What's the easiest way to scale soap recipes?

Use soap making software that automatically scales recipes. You enter your desired batch size, and it recalculates every ingredient—including lye and water—instantly without manual math.

Should I round up or down when scaling?

Never round lye. For oils, if you must round, round down slightly—this maintains your superfat safety margin. Better yet, don't round at all.

Conclusion

Scaling soap recipes is straightforward mathematics: multiply everything by the same factor. However, the precision required—especially for lye—makes manual calculations risky. One decimal point error can ruin a batch.

Most professional soap makers use software that handles scaling automatically. You input your desired batch size or mold dimensions, and the software recalculates every ingredient with perfect precision.

Whether you're testing a new recipe at small scale or ramping up production, accurate scaling is essential for consistent, safe soap.

Ready to Manage Your Recipes Like a Pro?

PotionHub helps soap and candle makers calculate lye, track batches, manage inventory, and grow their business.

Get PotionHub